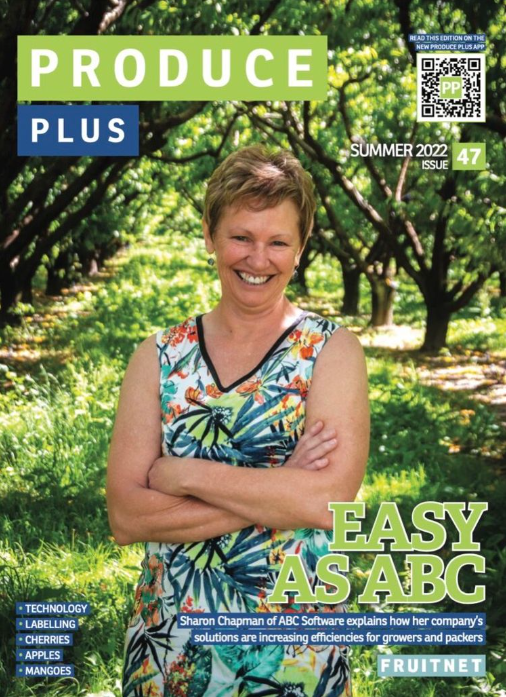

Sharon Chapman, founder and managing director of ABC Software, discusses the evolution of the New Zealand-headquartered company, which has a growing footprint in the Australian market.

By Matthew Jones

Can you begin by giving us a quick overview of the past 12 months for your company, ABC Software. Have you seen increased demand for your specialised software packages, and if so, what do you attribute this to?

There has definitely been an uptick in enquiries and sales. Given the escalating cost of labour and compliance, more growers are looking for digital solutions. ABC’s software packages are focused on giving decision making tools for operational insights, which is increasingly important given the labour and regulatory climate. Our growing reputation for providing quality, fit-for-purpose software, underpinned by really good support, is attracting new business.

You’ve recently launched some updates to your ABCgrower platform, including live productivity reporting and a new Business Intelligence API module. Can you tell us about these updates and the benefits they’re delivering to your customers?

To deliver on legislation changes introduced by Australia’s Fair Work Ombudsman (FWO) in April, we had to make enhancements. Catering for minimum wage calculations and top up payments was simple, as we have this legislation in New Zealand and our software already complied.

The tricky area was competency and the additional payment that should be made to competent, averagely productive pieceworkers. To do this we introduced the ability to record what we call intra-day times, that is the start and end time for a task. This allows us to show live productivity as the grower now has both quantity and duration.

Sounds simple, right? Well, not exactly. It took some effort and fine tuning to cater for various scenarios like individual workers moving between tasks or teams moving collectively from one task to the next. It needed to be easy to collect the data, and we worked hard at making it as simple as we could. We have great clients who give us really good feedback on what works and what doesn’t.

We have done a lot of work to give comprehensive block cost information within ABCgrower. Some of our clients want to take information from ABCgrower and combine it with information from other systems. This is where the Business Intelligence API comes into its own. Our clients can bring the ABCgrower data into tools like Microsoft Power BI, along with other data, to create holistic reporting.

You’ve also made updates to your ABCspray and ABCpacker solutions. Can you tell us about these?

We continue to finesse ABCspray, and have now included most of the feedback from our New Zealand and Australian clients. It’s reporting capabilities confirm with the various compliance and certification agencies, such as GlobalGAP. Our roadmap is to have offline capability to record the actual sprays used.

Regarding our packhouse software, ABCpacker, this is currently installed on-premise at the packhouse, as opposed to in the cloud. We have started developing a cloud-based solution that can run on-premise for those packhouse without internet access, and in the cloud for those that do. ABCpacker not only takes care of the packing and sales but has comprehensive packing inventory and grower payment modules as well.

Have these advances helped ABC Software attract new clients or extend its solutions to new categories?

As our reputation grows, so do opportunities to work with clients in new categories. We have clients across apples, avocados, berries, cherries, citrus, grapes, summerfruit, mangoes and more.

We’re recently begun working with a mushroom farm and are talking with onion and potato growers. We have built flexibility into our solutions to deliver fit-for-purpose software to cater for the variations in business processes and styles.

While you’re a New Zealand-headquartered company, you have a strong presence in the Australian market. How is your business developing in Australia?

Australia is a much larger market and has significant needs with the FWO changes. It becomes harder to use pen, paper and spreadsheets and stay compliant with the latest legislation. It is often challenging for the grower to adopt new processes such as software. Growers are traditionally time poor, so moving to digital automation is not usually in growers’ wheelhouse, and implementation takes effort before the rewards are evident. To this end, we work diligently with the grower through the on-boarding process. We have very responsive support and are only a phone call away with assistance and guidance when required.

A lot of effort has been put into making ABCgrower a great tool to meet the FWO rules and the Australian Horticulture Award in respect of worker’s time and pieces. We calculate top ups for minimum wage, show competency and productivity for the 15 percent uplift for the averagely productive, competent worker. ABCgrower can track hours for overtime payments, such as a causal worker exceeding 304 hours over eight weeks. It can be used by the grower to see their costs in real-time, and not wait for a payroll to be completed, by which time it is too late to make operational decisions.

Jenkins Group, which specialise in end-to-end packaging solutions for the fresh produce industry, recently invested in your company. Can you tell us about the deal and how it will drive new innovation at ABC Software?

The Jenkins Group is known by many in Australia as J-Tech Systems. In addition to packaging, they are very active in the automation space with the award winning Aporo, an automated apple packer.

Jenkins saw ABC as having innovative software also operating in the horticulture industry. The relationship is still new, and discussions are current on how to best digitise and automate solutions for the client base to bring efficiencies and value for all. However, with like-minded values, the Jenkins Group is a great company to be aligned with, and ABC is enjoying the new relationship.

Published in Produce Plus Summer 2022 Issue 47